Aluminum gravity cast gas pipe

The aluminum gravity casting gas pipe must be a challenge for us.

The two ends of the gravity cast gas pipe are two circles which must be concentric. Furthermore,the aluminum gas pipe is a taper gas,that means the inner sand core which is used to achieve the taper feature must has one end heavier than the other. Such uneven sand core is subject to moving.

And as gas application, the aluminum gravity cast pipe must be gas tight.So the inner porosity is critical for the whole casting.

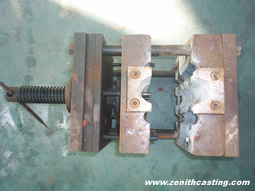

The gravity casting mold and sand core injection mold were carried out as scheduled smoothly. We injected the first batch of resin sand cores. The sand cores were sorted carefully to pick out any one even with slightly concentric deviation. Where the selected resin sand cores are ready, we started to test the permanent mold.

The permanent metal mold like high pressure die casting mold should be heated to likely temperature for casting. It is a regular step before casting.

When the mold temperature rise to the right point, we add powder lubricant to the cavity of the metal mold.Then the resin sand core was added into the metal mold.

We designed two attaching location for the permanent mold. Herewith, the sand core can be fixed to the permanent mold steady. In order to guarantee the steadiness, we chose our horizontal gravity casting machine to cast the gas pipe, not the much flexible tilting gravity casting machine. Because the tilting machine should be tilted from horizontal to vertical that can loose the sand core attachment.

Although we took in consideration whatever we could think, the first samples were quite not satisfactory.

The concentric was really a trouble for us. Besides the concentric, the uneven wall thickness was the other troublesome thing. We thought we fell into a difficulty which might not be overcome.

The first correction proposal was to adjust the mold to tighten the sand core attaching point. We thought the concentric deviation must be resulted from the loosing of sand core attachment. But evenly we tightened the attaching point and selected the resin sand core much more strictly, the second time of samples still failed. The cast gas pipe still had deformation and uneven wall thickness.

Our casting engineer was anxious about the project. We inspected the resin sand cores carefully,because we considered the sand core could be the main reason. We injected a new batch of sand cores which is harder and much steadier than the former batch. But the reinforced sand cores still can solve the casting trouble.

The permanent mold was adjusted for the second time,but the terrible problem was still not solved. We were just sad for the casting gas pipe. At last, we even changed the vertical cavity to a horizontal one. But the casting still can make us satisfied.

It might be a ashamed case for us. But we really can not overcome the high tight concentric requirement, although we can meet the gas tight requirement. We refunded the down payment to our customer and addressed an official letter for their forgiveness.

Quick Inquiry of Casting

For any question about aluminum or brass sand casting and gravity casting, please contact us directly via following means:

P:Ms.Elandy Chen

T:+86 574 8865 1898

E: sales@zenithcasting.com